Composite Decking is a popular choice among homeowners and contractors alike. It’s affordable, stylish, durable, and easier to install than traditional hardwood. But just because it’s easier doesn’t mean it’s foolproof. In fact, improper installation can cost you more in repairs, reduce the lifespan of your flooring, and even void your warranty. Whether you're a DIY enthusiast or hiring a professional, avoiding common mistakes during installation is crucial.

In this blog, we’ll uncover 12 of the most common mistakes people make when installing composite decking, and more importantly, how to avoid them. From expansion gaps to ventilation, we’ve got every detail covered to help you get the most from your flooring investment.

Composite Decking is a composite product made from wood fibers and plastic resins. Unlike traditional wood, it reacts more noticeably to environmental changes such as temperature, moisture, and humidity. That’s why correct installation is not just a recommendation—it’s essential.

Warping and buckling

Moisture damage

Structural instability

Early wear and tear

Voided warranties

The Problem:

Composite Decking expands and contracts with temperature changes. Without proper expansion gaps at the ends, boards can warp or lift.

The Fix:

Leave expansion joints based on your environment:

Above 26°C: 1mm

4°C–25°C: 3mm

Below 4°C: 6mm

Don’t underestimate this step—it’s one of the most overlooked but crucial elements of a successful install.

The Problem:

If the wood fibers in laminate absorb moisture without proper air circulation, mold and rot can develop underneath.

The Fix:

Ensure a minimum of 35mm space between the flooring and any base (like concrete or soil). This promotes airflow and prevents hidden moisture buildup.

The Problem:

Old wooden frames or soft materials might not provide enough support and are vulnerable to water damage.

The Fix:

Use plastic or steel underframes in moisture-prone areas and increase joist density for better load-bearing.

The Problem:

Old wooden keels may have lost strength, and hidden decay can cause uneven surfaces and instability.

The Fix:

For high-traffic or wet zones, opt for steel or plastic frames. If wood is used, ensure it’s thoroughly dried and treated.

The Problem:

Traditional wooden floor spacing (500mm) is too wide for composite decking, leading to bowing or sagging.

The Fix:

Keep joist spacing between 250–350mm. This tighter layout provides the necessary support for thinner, more flexible laminate boards.

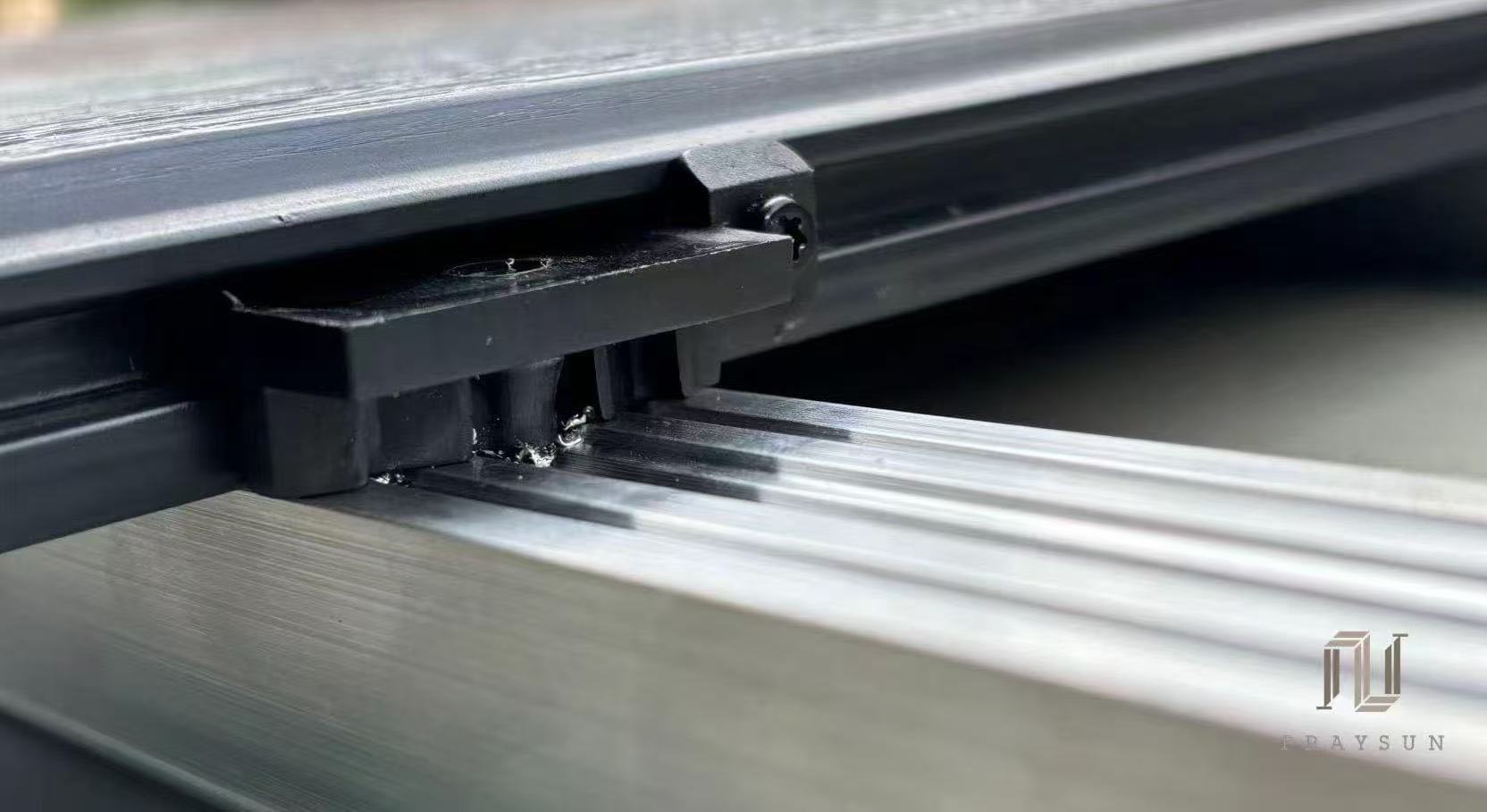

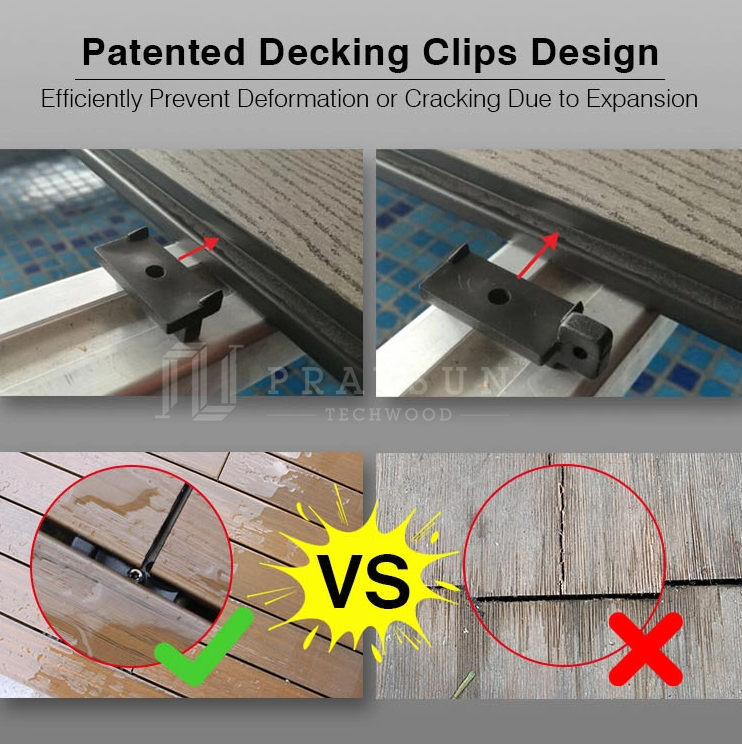

The Problem:

Generic or mismatched clips can cause installation issues due to incompatible expansion tolerances.

The Fix:

Stick to original brand accessories like Praysun® clamps, which are engineered for perfect compatibility.

The Problem:

Direct screws can crack boards over time and restrict natural movement, often voiding your warranty.

The Fix:

Always use the manufacturer’s recommended clamp system. It allows movement and protects structural integrity.

The Problem:

Exposed wood ends on keels absorb moisture quickly, accelerating rot.

The Fix:

Treat all wood—especially cut ends—with anti-rot sealant before installation. Prevention is easier than repair.

The Problem:

Joints longer than 3.6 meters without double support are prone to cracking or movement.

The Fix:

Install double keels beneath long joints and follow correct spacing guidelines based on your local climate.

The Problem:

Each brand has specific materials, expansion rates, and structural requirements.

The Fix:

Always follow the official Praysun® installation guide (or your brand's equivalent). Never assume one-size-fits-all.

The Problem:

A level surface can cause water to pool, leading to slippery floors and structural damage.

The Fix:

Build in a 1% drainage slope (about 10mm per meter), directing water away from your building.

The Problem:

Not all laminate boards are equal—hollow slabs don’t handle weight like solid ones.

The Fix:

Use hollow slabs in low-load areas like patios or balconies.

Opt for solid boards in heavy-use zones like rooftops, terraces, and hot tub platforms.

Installing composite decking can seem straightforward, but missing small details can lead to major issues down the line. Whether it's skipping expansion gaps or ignoring drainage, each misstep has a cost.

By following these professional tips—and sticking to brand-specific guidelines—you can enjoy a floor that looks stunning, performs flawlessly, and lasts for years.

Pro tip: Always use high-quality materials and original accessories like those from Praysun®, which are designed to work in perfect harmony with your laminate boards.

praysunmaterials@gmail.com